End Mill

Best Quality, Excellent Service

-

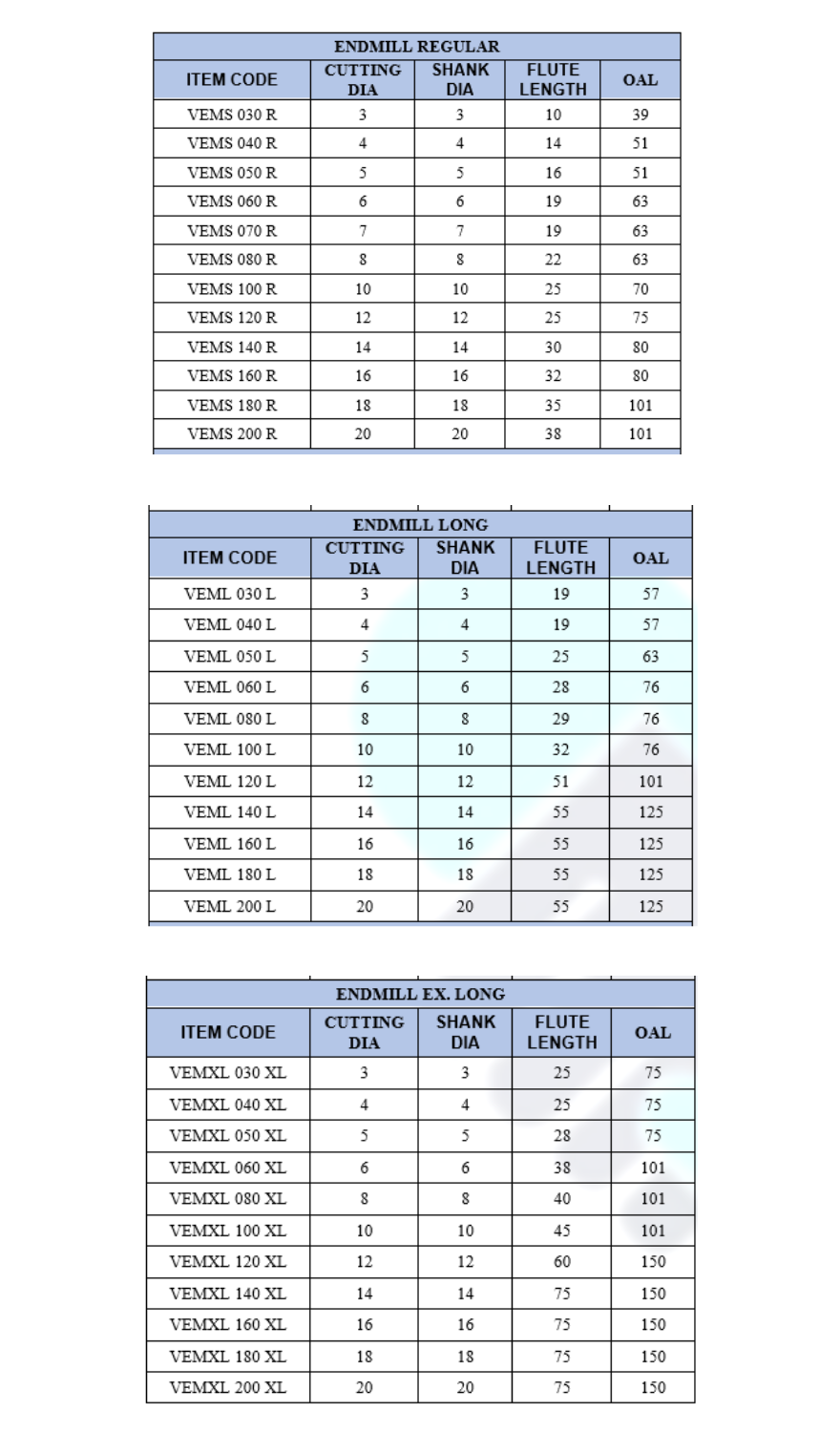

Endmill Regular

An end mill is a type of milling cutter used in machining operations to remove material from a workpiece. It has cutting edges on the bottom and sides, allowing it to perform a variety of milling tasks such as slotting, profiling, and contouring. Here are some regular details about end mills:

- Material: End mills are typically made from high-speed steel (HSS), cobalt steel, or solid carbide. Solid carbide end mills are more durable and can withstand higher cutting speeds and temperatures.

- Application: Different types of end mills are suitable for specific applications. For example, square end mills are commonly used for general milling and slotting, while ball end mills are ideal for contouring and 3D machining.

It's important to choose the right type of end mill for your specific machining task to achieve the desired results in terms of accuracy, surface finish, and efficiency.

-

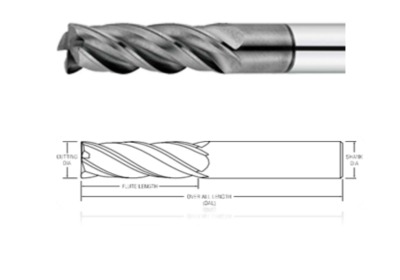

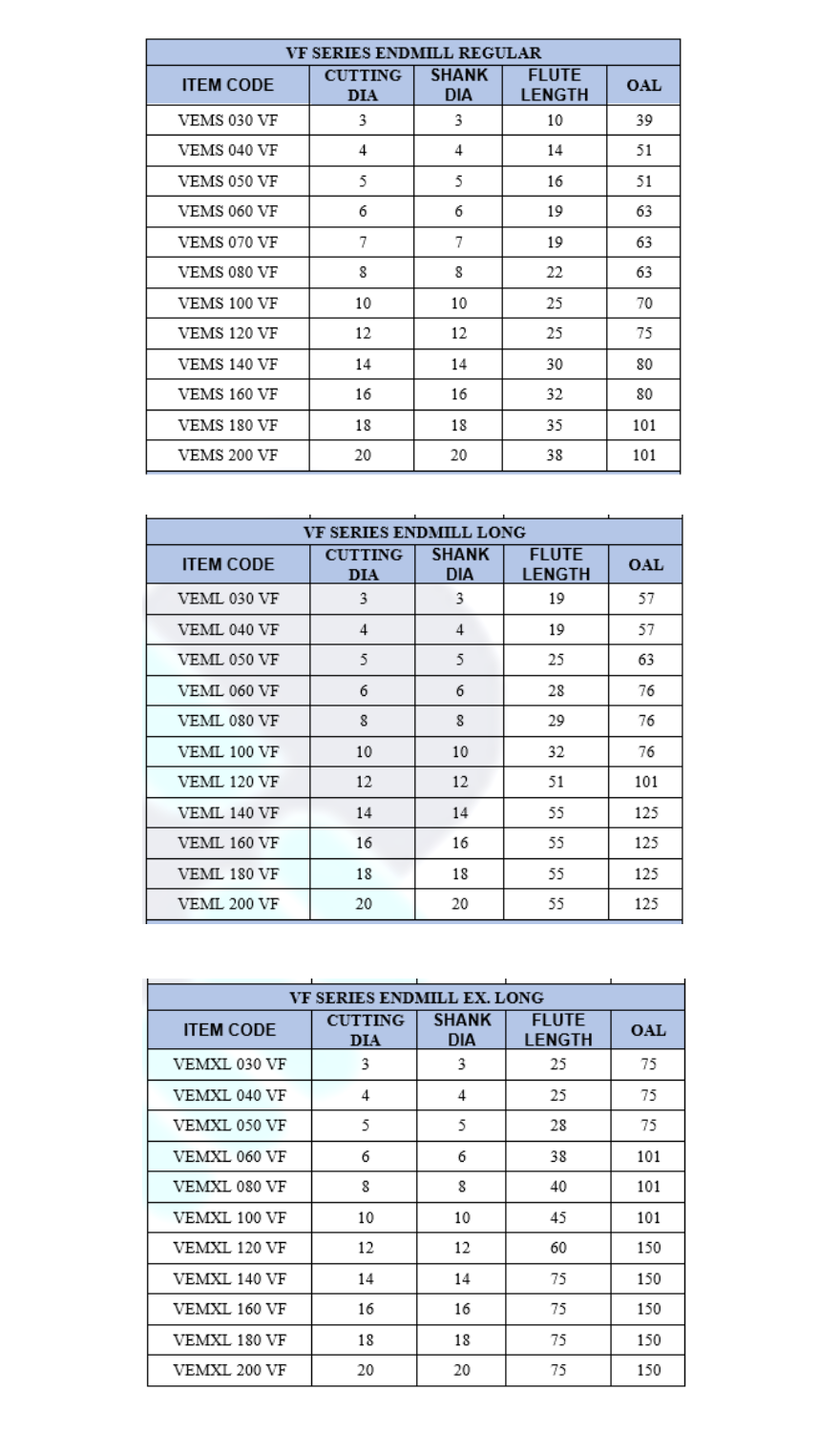

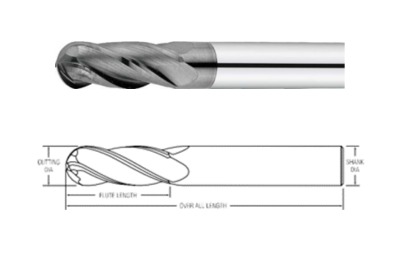

VF Series Endmill

The VF series end mills are a specific line of end mills offered by various manufacturers, including manufacturers such as Guhring, OSG, and Kennametal. While I don't have access to specific details about every manufacturer's VF series, I can provide you with some general information about end mills in this category.

- Versatility: The VF series end mills are designed to be versatile and capable of handling a wide range of milling operations. They are often used in general-purpose milling applications, such as milling slots, pockets, and contours in various materials.

It's important to refer to the manufacturer's specific documentation and catalog for detailed information about their VF series end mills, as different manufacturers may have variations in design, features, and specifications within this series.

-

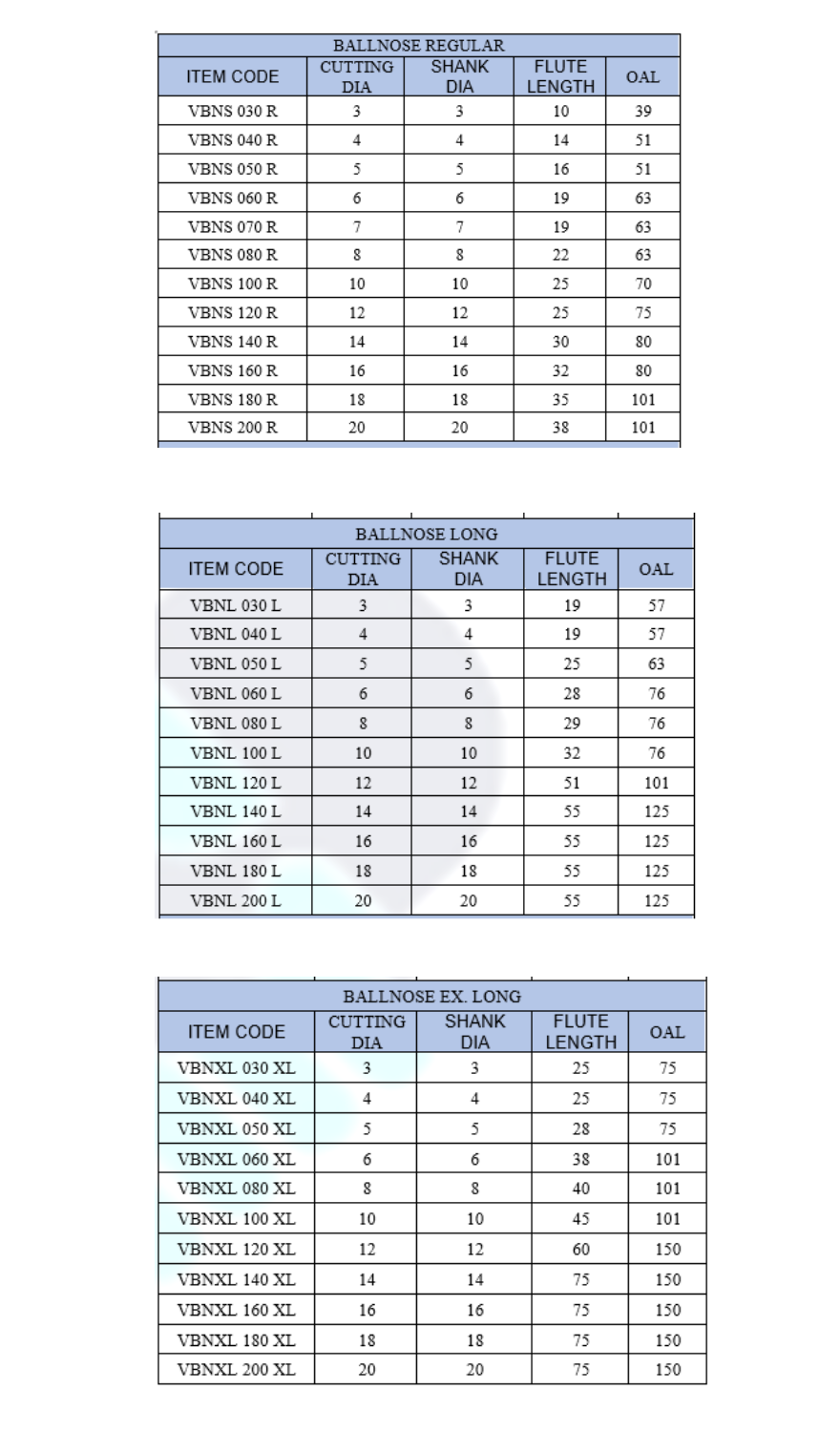

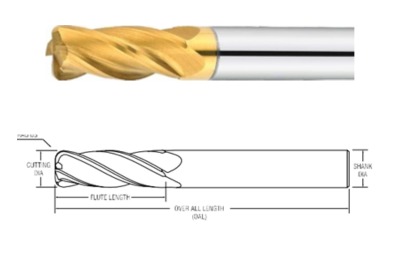

Ballnose

Ballnose end mills, also known as ball end mills or spherical end mills, are a type of milling cutter that have a rounded end shape. Here are some details about ballnose end mills:

- Geometry: Ballnose end mills have a rounded cutting end, resembling a ball or sphere. This shape allows for contouring, profiling, and 3D machining operations, as the rounded end can create smooth curves and transitions.

- Application: Ballnose end mills are commonly used in 3D contouring, surface machining, and profile milling operations. They are suitable for machining complex shapes, curved surfaces, and intricate features.

When selecting a ballnose end mill, consider factors such as the desired surface finish, material being machined, depth of cut, and machining parameters to ensure optimal performance and results. Manufacturers' catalogs and specifications provide more detailed information about specific ballnose end mills available in the market.

-

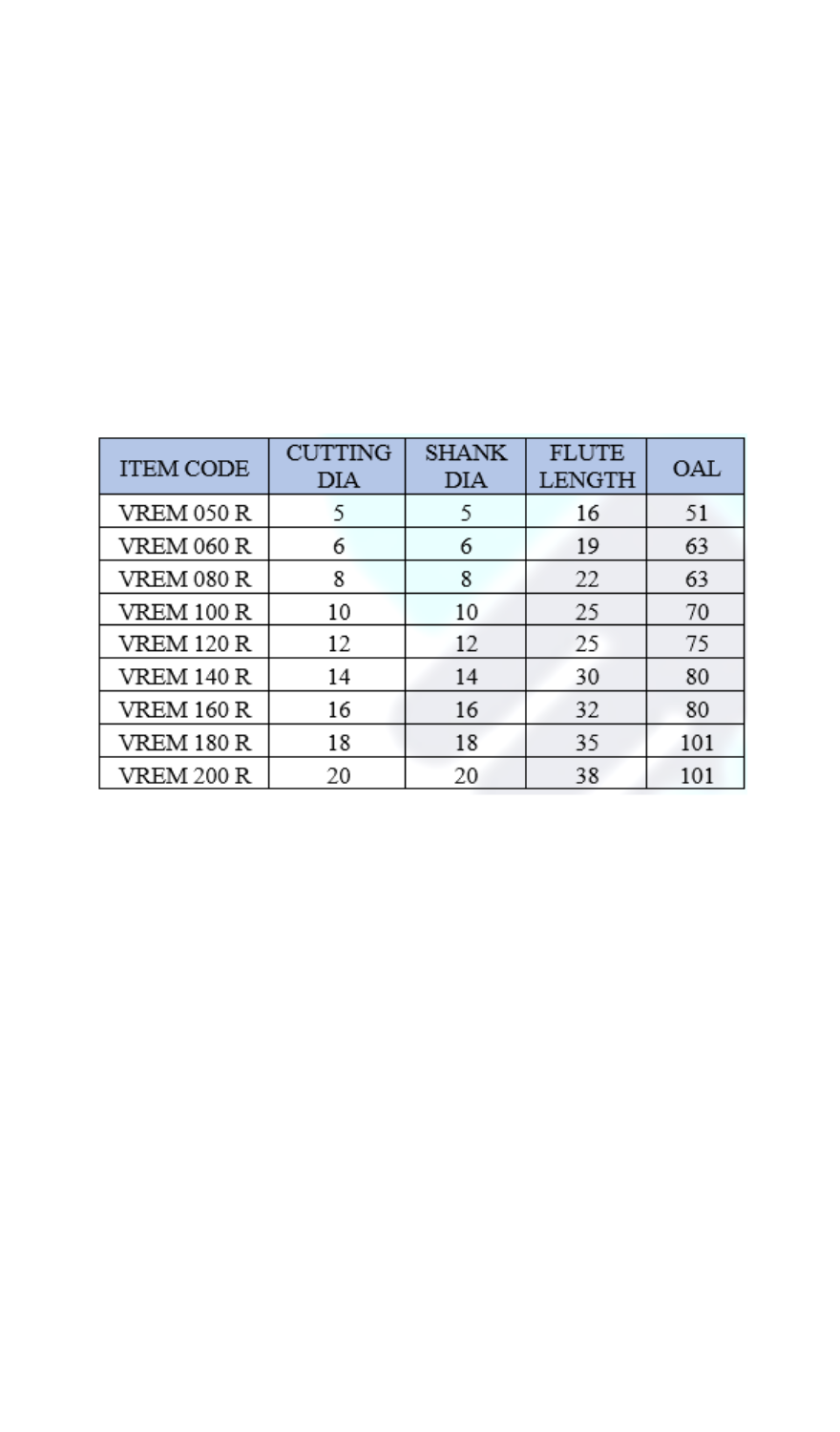

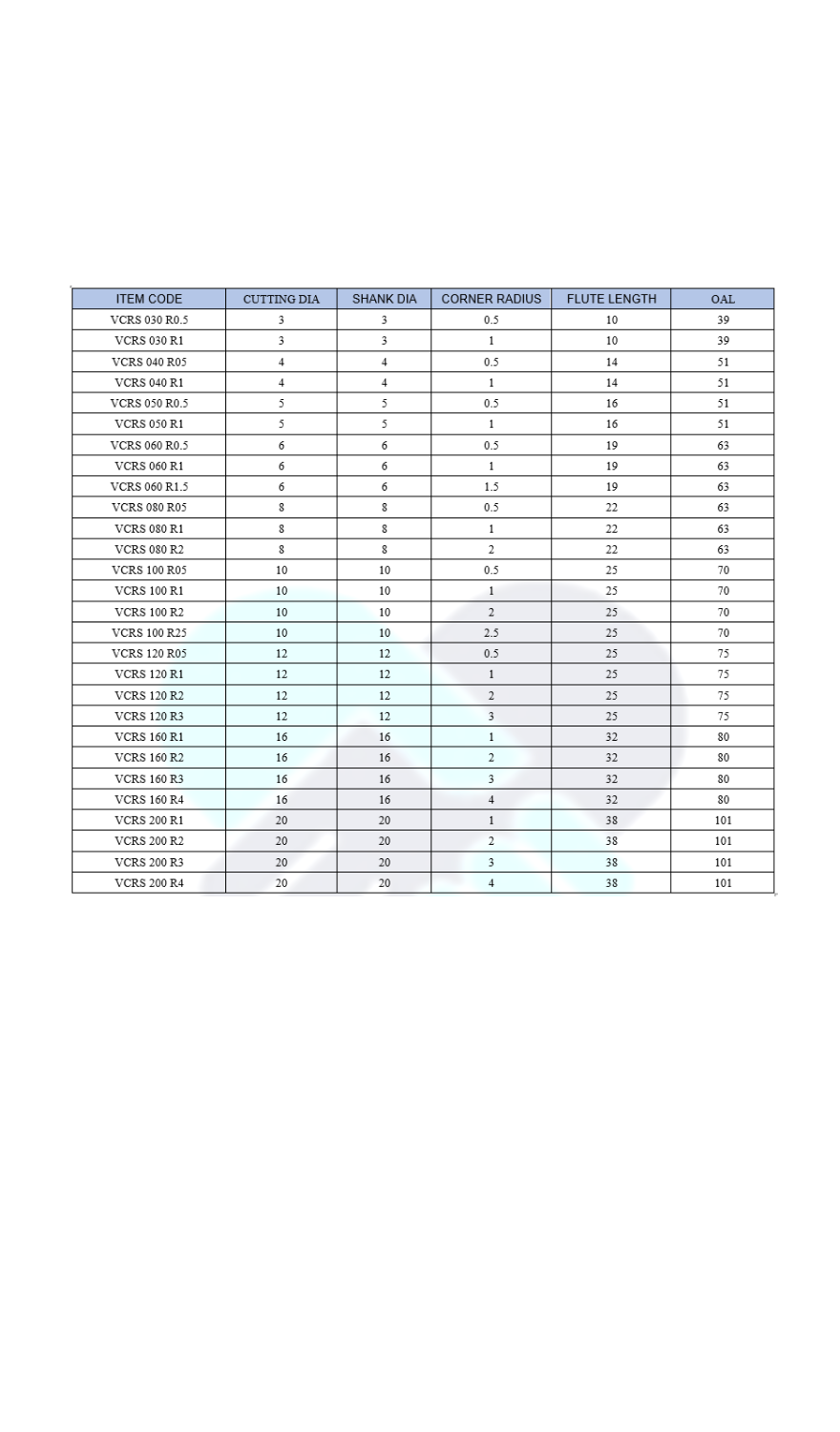

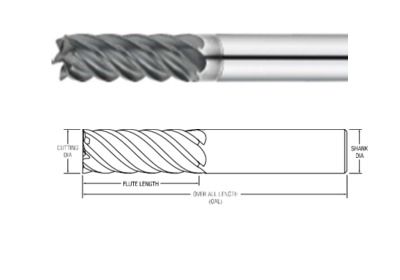

Corner Radius Endmill

Corner radius end mills, also known as bull nose end mills, are a type of milling cutter that have a rounded corner at the cutting end. Here are some details about corner radius end mills:

- Application: Corner radius end mills are commonly used in machining operations where a rounded corner is desired, such as creating fillets, rounding edges, and contouring curved surfaces. They offer improved tool life, reduced stress, and enhanced surface finish compared to sharp-cornered end mills.

When selecting a corner radius end mill, consider factors such as the desired radius size, material being machined, depth of cut, and machining parameters to ensure optimal performance and results. Manufacturers' catalogs and specifications provide more detailed information about specific corner radius end mills available in the market.

-

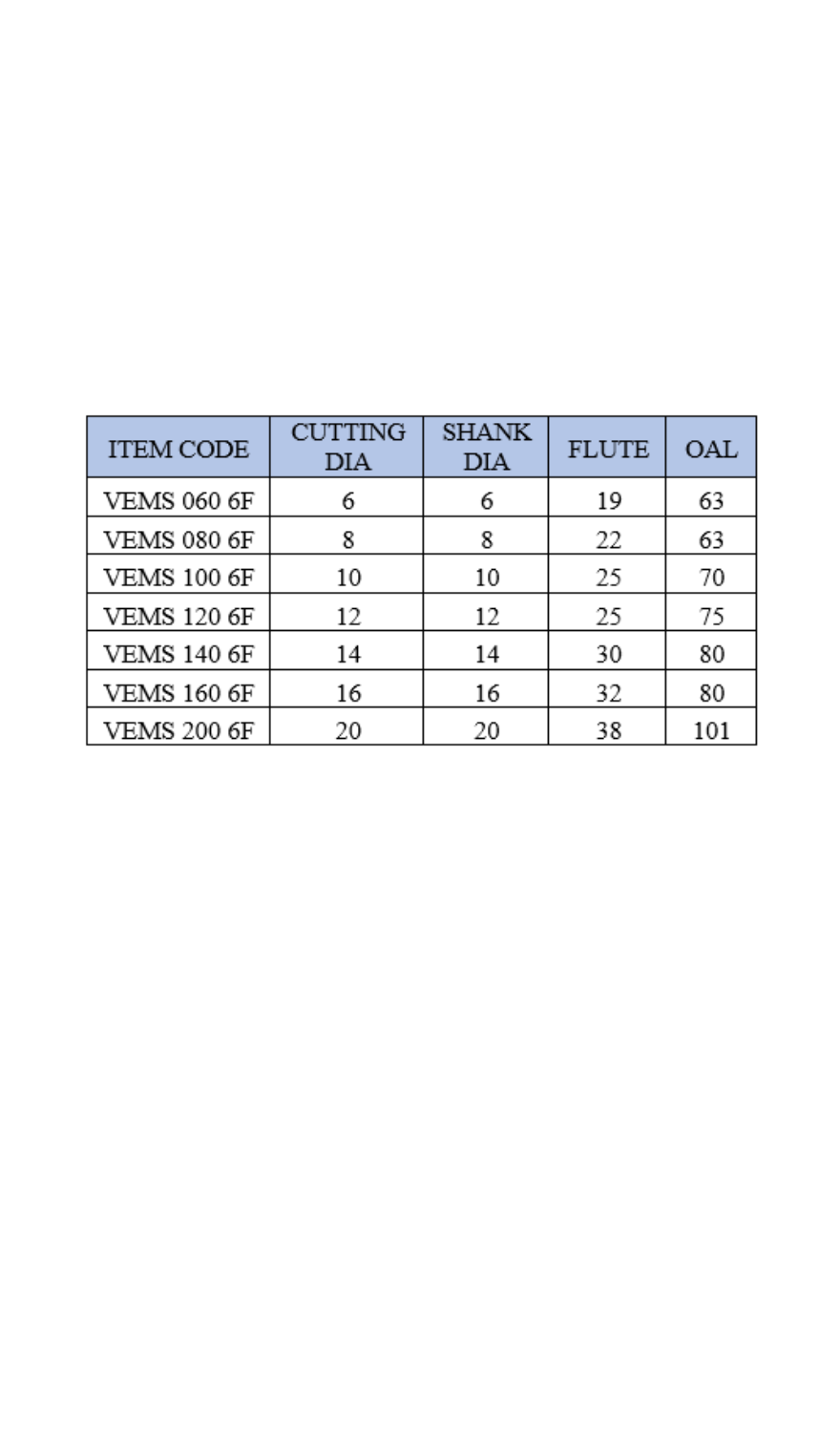

6 Flute Endmill

A 6-flute end mill refers to an end mill that has six cutting flutes or edges. Here are some details about 6-flute end mills:

- Application: 6-flute end mills are often used in heavy-duty machining operations where high material removal rates are desired. The additional flutes distribute cutting forces more evenly, allowing for efficient chip evacuation and reducing the likelihood of tool deflection.

It's important to consider factors such as the material being machined, cutting parameters, and desired surface finish when selecting a 6-flute end mill. Manufacturers' catalogs and specifications provide more detailed information about specific 6-flute end mills available in the market.

-

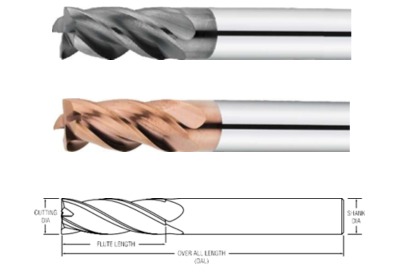

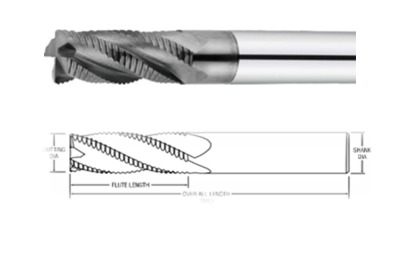

Rougher Endmill

A rougher end mill, also known as a roughing end mill, is a type of milling cutter specifically designed for aggressive material removal during roughing operations. Here are some details about rougher end mills:

- Application: Rougher end mills are primarily used for roughing operations, where material removal is the primary objective rather than achieving a high-quality surface finish. They are commonly used in rough milling, slotting, and heavy-duty machining of tough materials.

It's important to choose the right rougher end mill based on factors such as the material being machined, cutting parameters, and desired stock removal rate. Manufacturers' catalogs and specifications provide more detailed information about specific rougher end mills available in the market.