Drill

Best Quality, Excellent Service

-

Drill 3XD Series

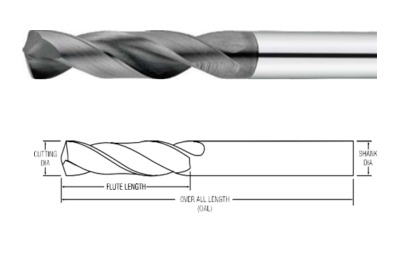

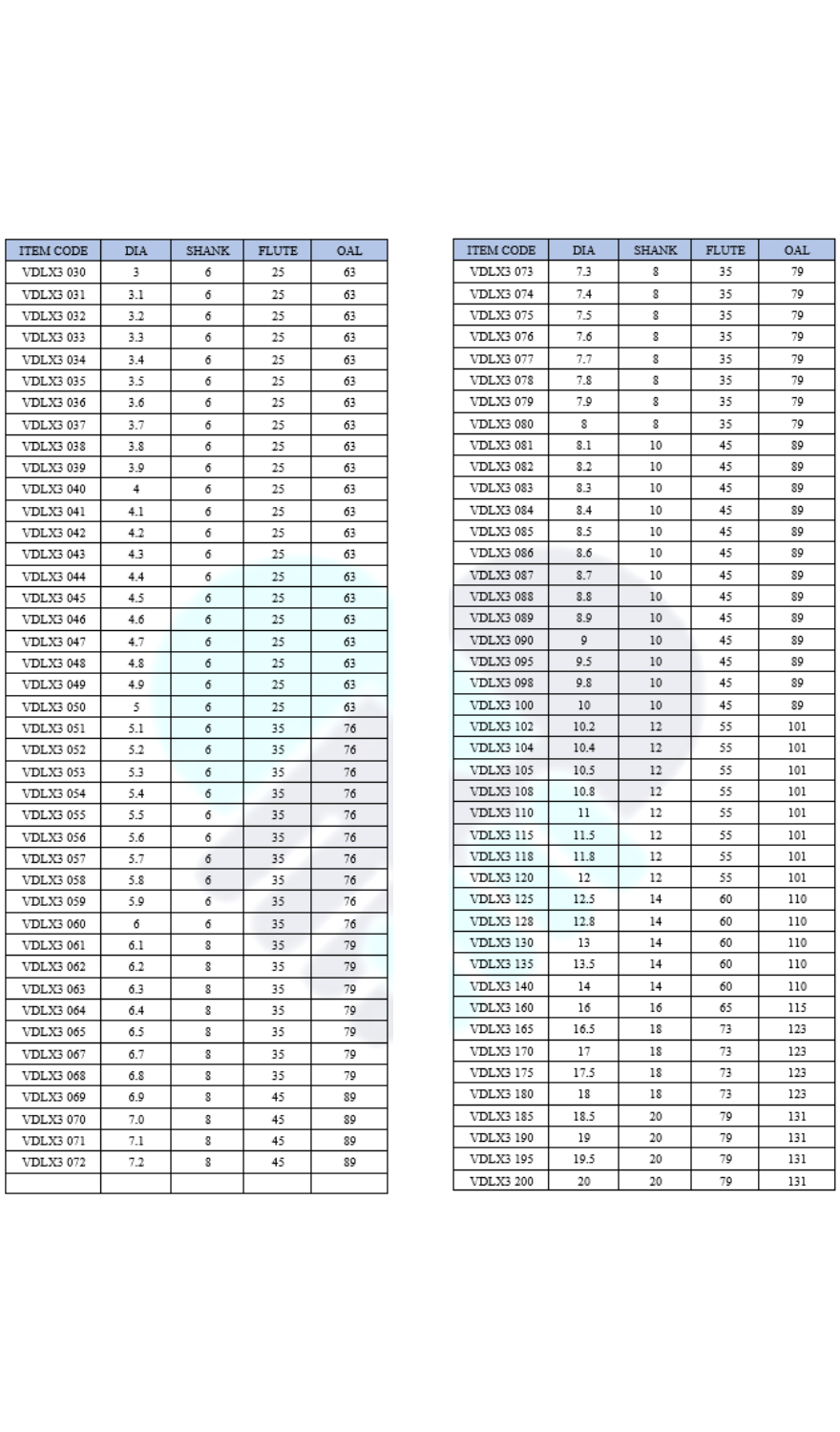

The "3xD" series refers to a specific type of drill that has a drilling depth of approximately three times the diameter of the drill. Here are some details about the 3xD drill series:

- Application: 3xD drills are suitable for a wide range of drilling applications where a moderate drilling depth is required. They are commonly used in general-purpose drilling, hole-making, and maintenance operations.

- Material: 3xD drills are typically made from high-speed steel (HSS), cobalt steel, or solid carbide. The choice of material depends on the specific drilling application, such as the type of material being drilled and the desired tool life.

When selecting a 3xD drill, consider factors such as the material being drilled, drilling parameters (such as speed and feed rate), and desired hole quality to ensure optimal performance and results. Manufacturers' catalogs and specifications provide more detailed information about specific 3xD drill options available in the market.

-

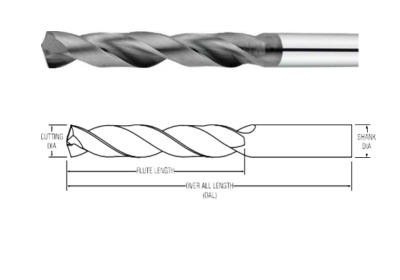

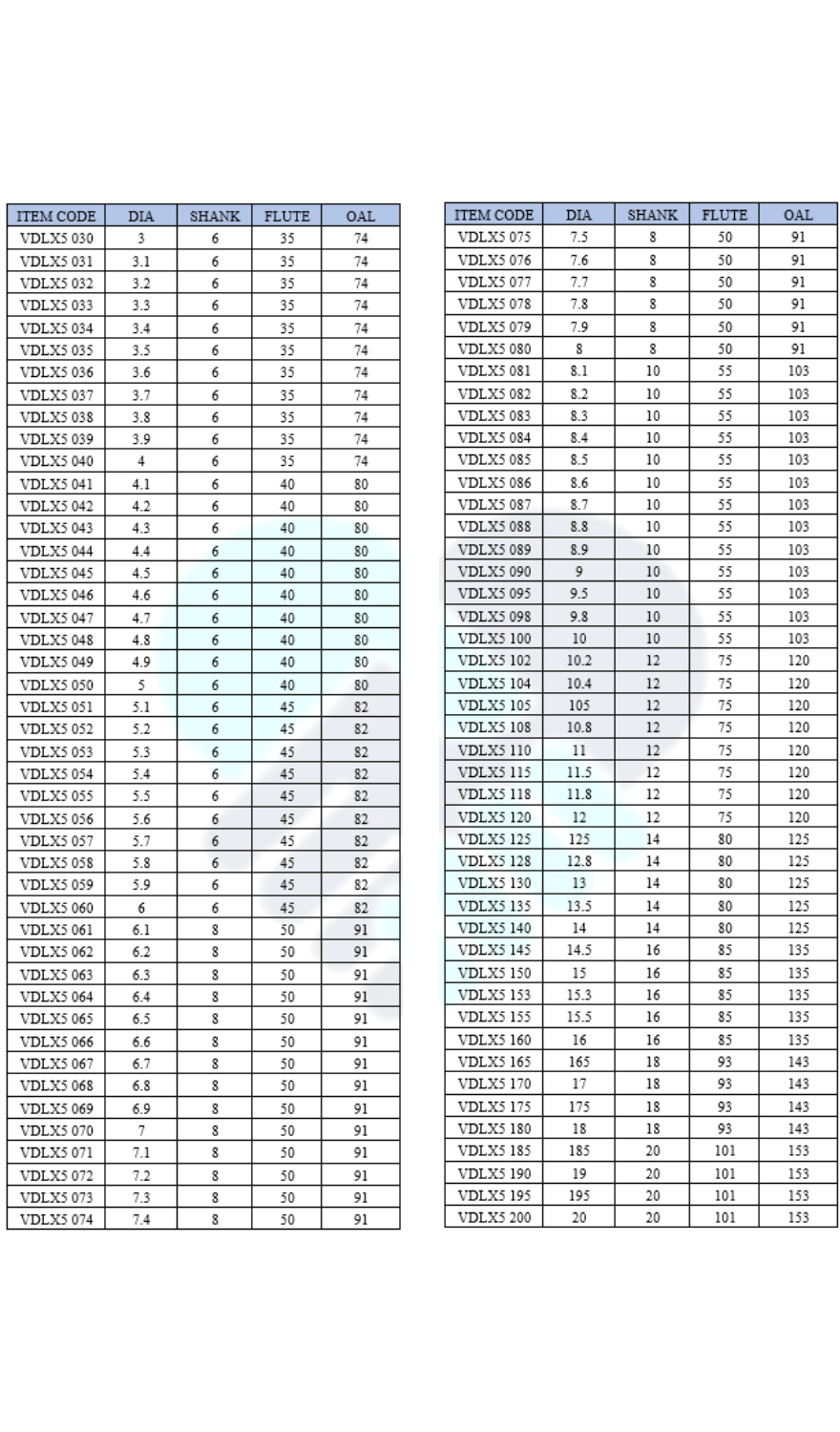

Drill 5XD Series

The "5xD" series refers to a specific type of drill that has a drilling depth of approximately five times the diameter of the drill. Here are some details about the 5xD drill series:

- Application: 5xD drills are suitable for applications where a deeper drilling depth is required, offering increased versatility compared to shorter drills. They are commonly used in general-purpose drilling, hole-making, and maintenance operations.

When selecting a 5xD drill, consider factors such as the material being drilled, drilling parameters (such as speed and feed rate), and desired hole quality to ensure optimal performance and results. Manufacturers' catalogs and specifications provide more detailed information about specific 5xD drill options available in the market.

-

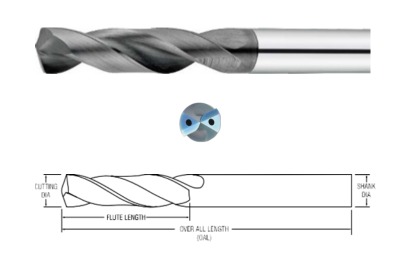

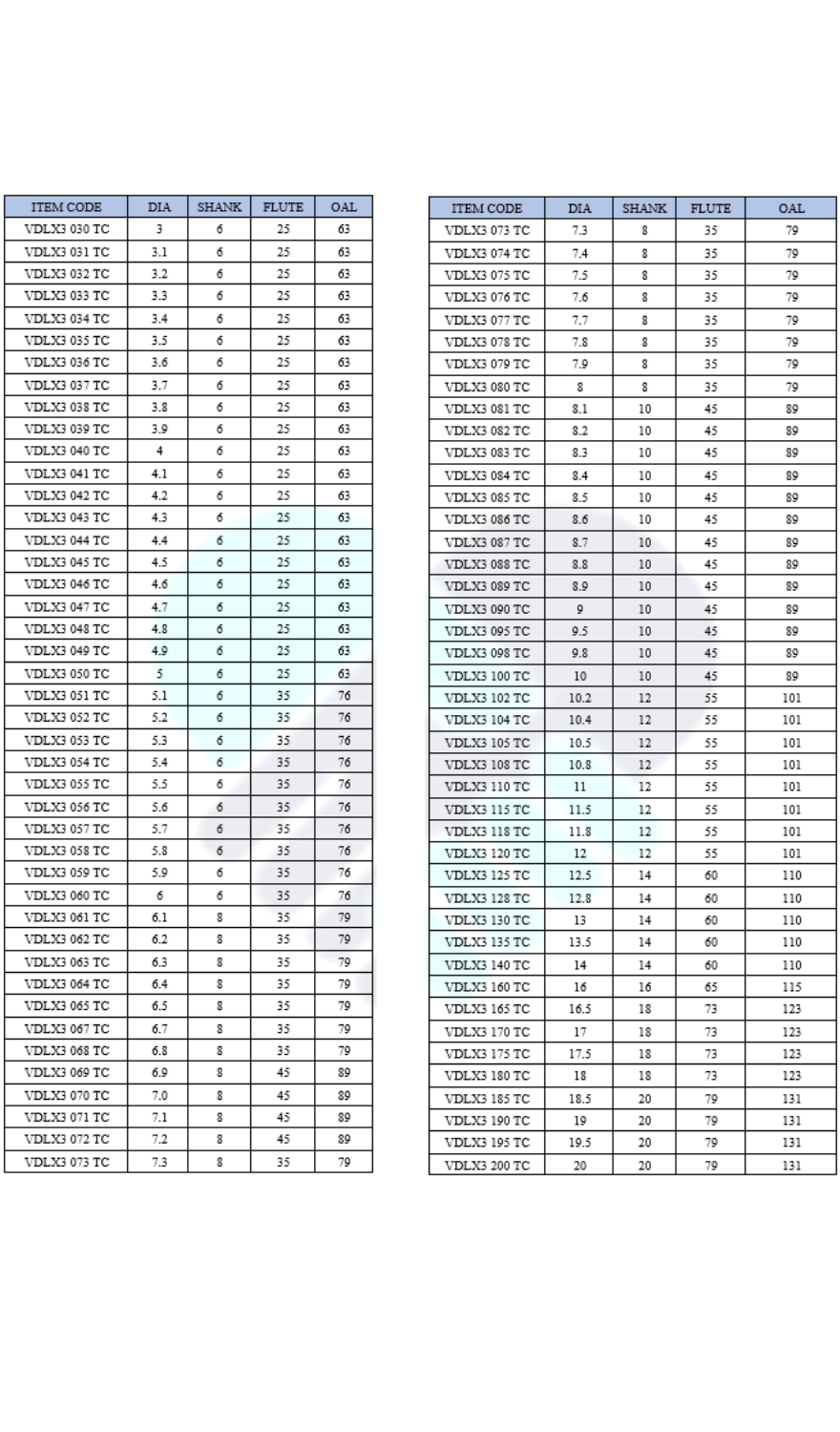

Through Coolant Drill 3XD Series

A "through coolant 3xD" series refers to a specific type of drill that has a drilling depth of approximately three times the diameter of the drill and features coolant holes to facilitate the flow of coolant directly to the cutting edge during the drilling process. Here are some details about the through coolant 3xD drill series:

- Application: Through coolant 3xD drills are suitable for applications where efficient chip evacuation and effective cooling are essential, particularly in deep-hole drilling or when working with difficult-to-machine materials. They are commonly used in general-purpose drilling, hole-making, and manufacturing operations that require improved chip control and reduced heat generation.

When selecting a through coolant 3xD drill, consider factors such as the material being drilled, cutting parameters, coolant availability, and desired hole quality to ensure optimal performance and results. Manufacturers' catalogs and specifications provide more detailed information about specific through coolant 3xD drill options available in the market.

-

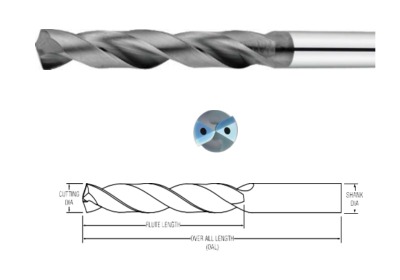

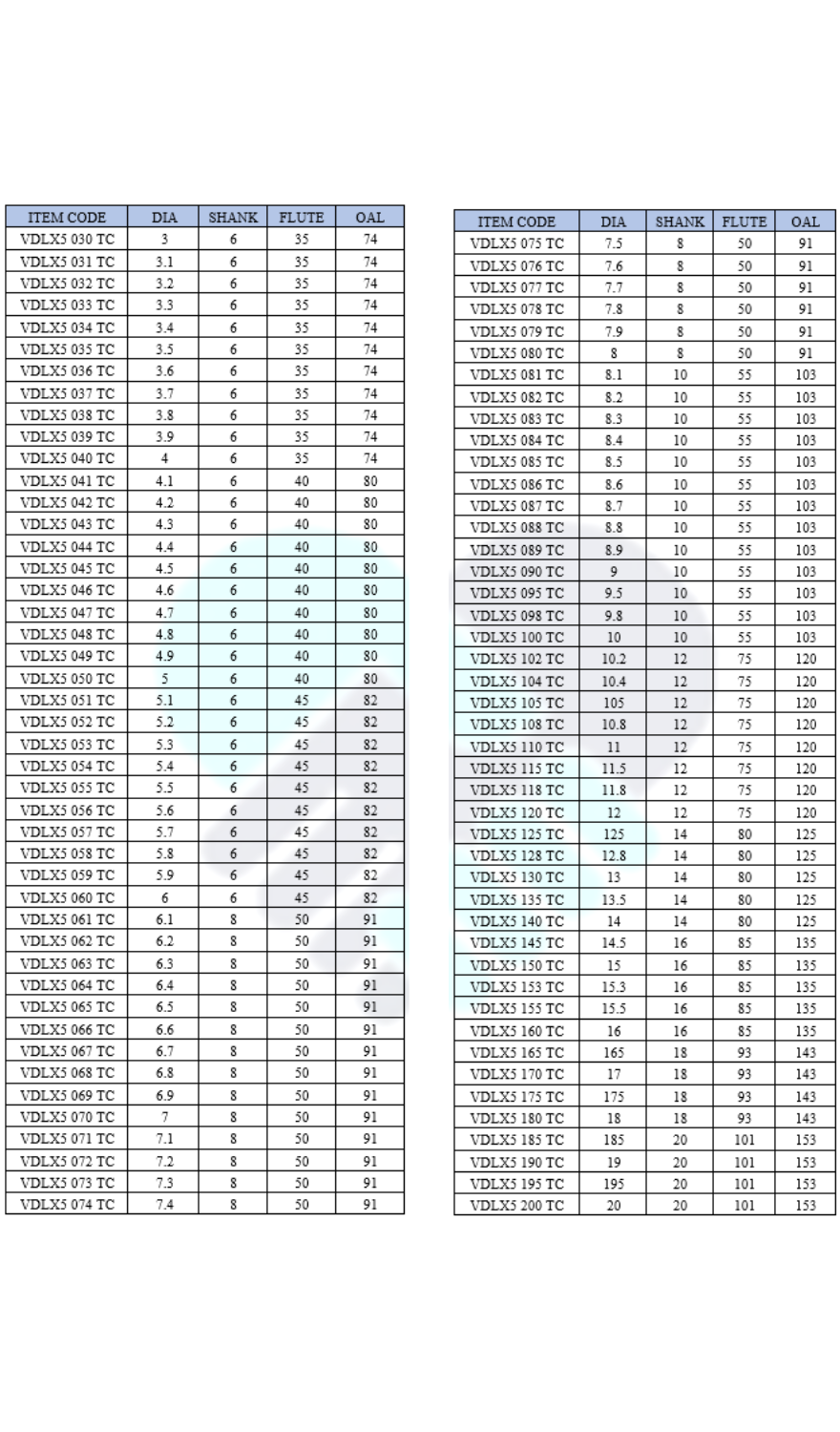

Through Coolant Drill 5XD Series

A "through coolant 5xD" series refers to a specific type of drill that has a drilling depth of approximately five times the diameter of the drill and features coolant holes to facilitate the flow of coolant directly to the cutting edge during the drilling process. Here are some details about the through coolant 5xD drill series:

- Application: Through coolant 5xD drills are suitable for applications where efficient chip evacuation and effective cooling are essential, particularly in deep-hole drilling or when working with difficult-to-machine materials. They are commonly used in general-purpose drilling, hole-making, and manufacturing operations that require improved chip control and reduced heat generation.

When selecting a through coolant 5xD drill, consider factors such as the material being drilled, cutting parameters, coolant availability, and desired hole quality to ensure optimal performance and results. Manufacturers' catalogs and specifications provide more detailed information about specific through coolant 5xD drill options available in the market.

-

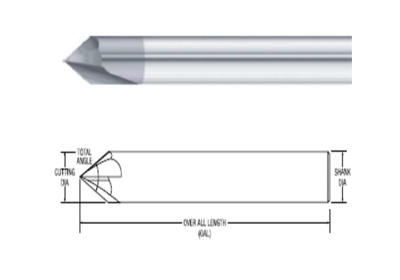

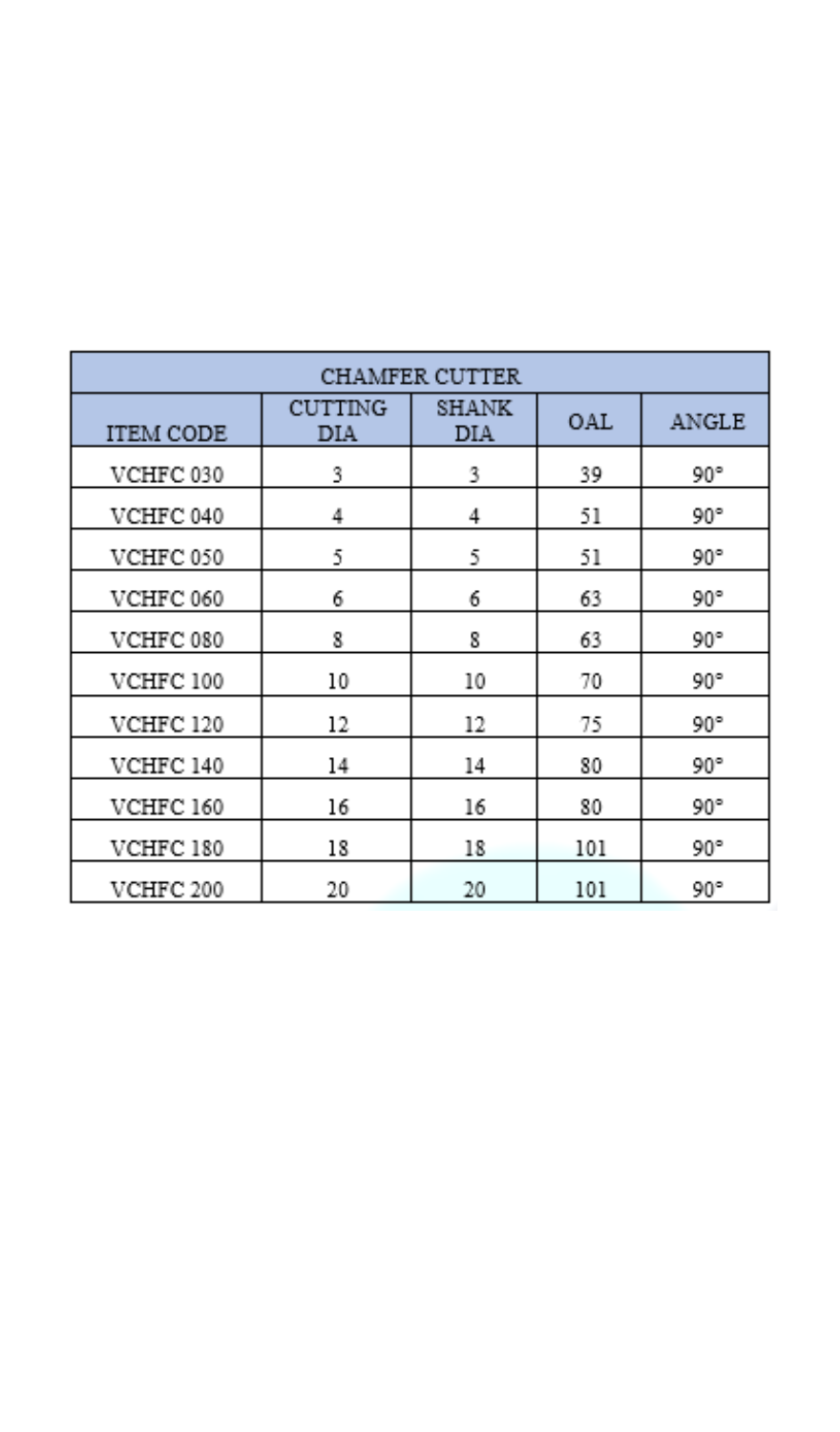

Chamfer Cutter

A chamfer cutter, also known as a chamfer end mill or chamfering tool, is a cutting tool used to create chamfered edges or beveled angles on a workpiece. Here are some details about chamfer cutters:

- Application: Chamfer cutters are primarily used to create chamfered edges on workpieces. Chamfers can be created for various reasons, such as providing a finished look, removing sharp edges, facilitating assembly, or improving part functionality. Chamfer cutters are commonly used in machining operations, woodworking, metal fabrication, and other industries.

It's important to consider factors such as the material being machined, chamfer size and angle, cutting parameters, and desired surface finish when selecting a chamfer cutter. Manufacturers' catalogs and specifications provide more detailed information about specific chamfer cutter options available in the market.

-

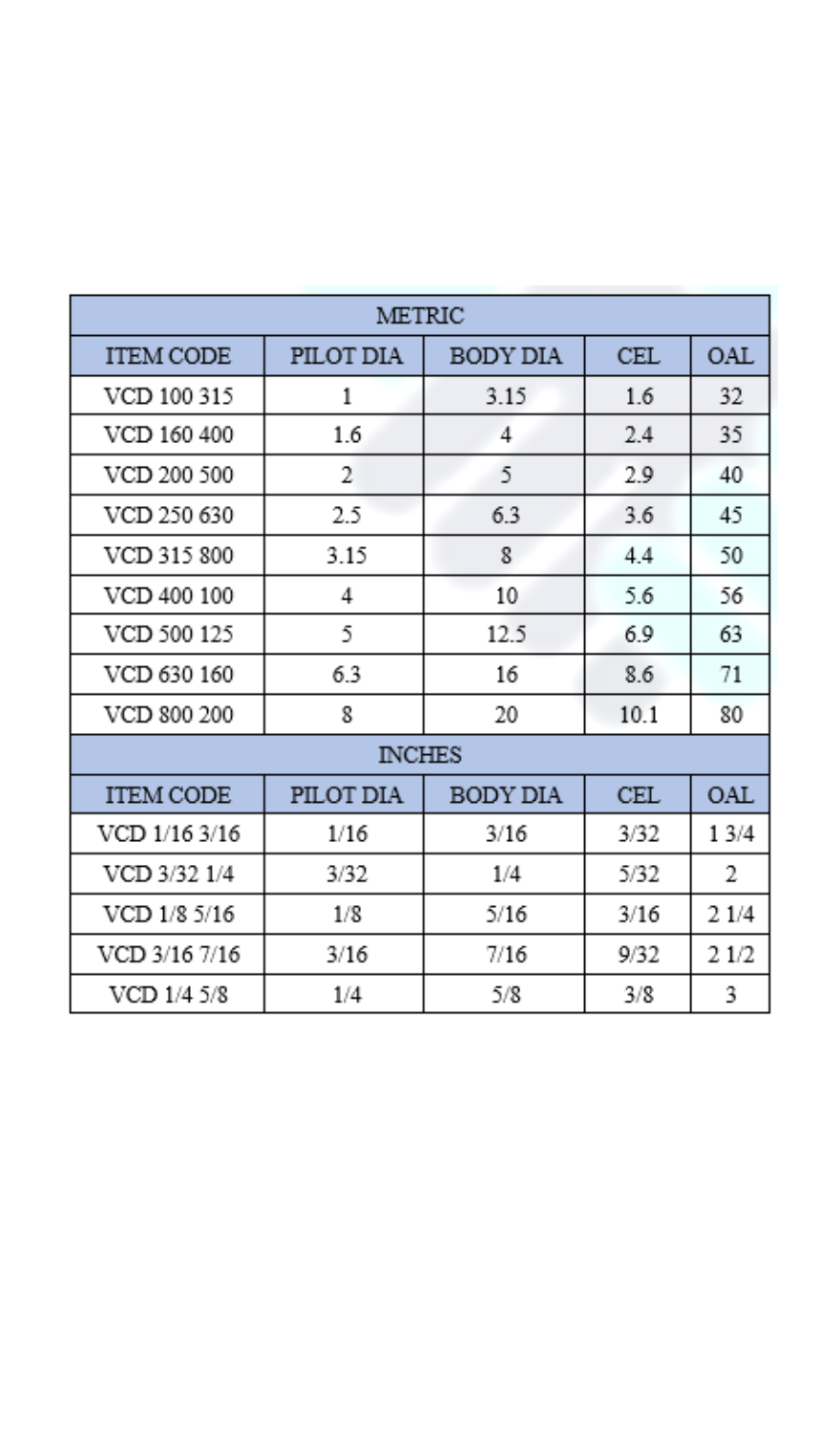

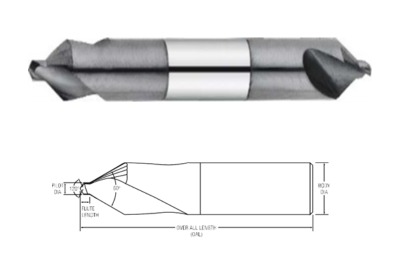

Center Drill

A center drill, also known as a spotting drill or centering drill, is a specialized cutting tool used to create a starting point or center hole for subsequent drilling operations. Here are some details about center drills:

- Application: Center drills are commonly used in metalworking, woodworking, and other industries where precise hole alignment is critical. They are especially useful when drilling on rounded or curved surfaces, or when starting a hole on a flat surface where accuracy is important.

Manufacturers' catalogs and specifications provide more detailed information about specific center drill options available in the market, including various sizes, coatings, and other features.